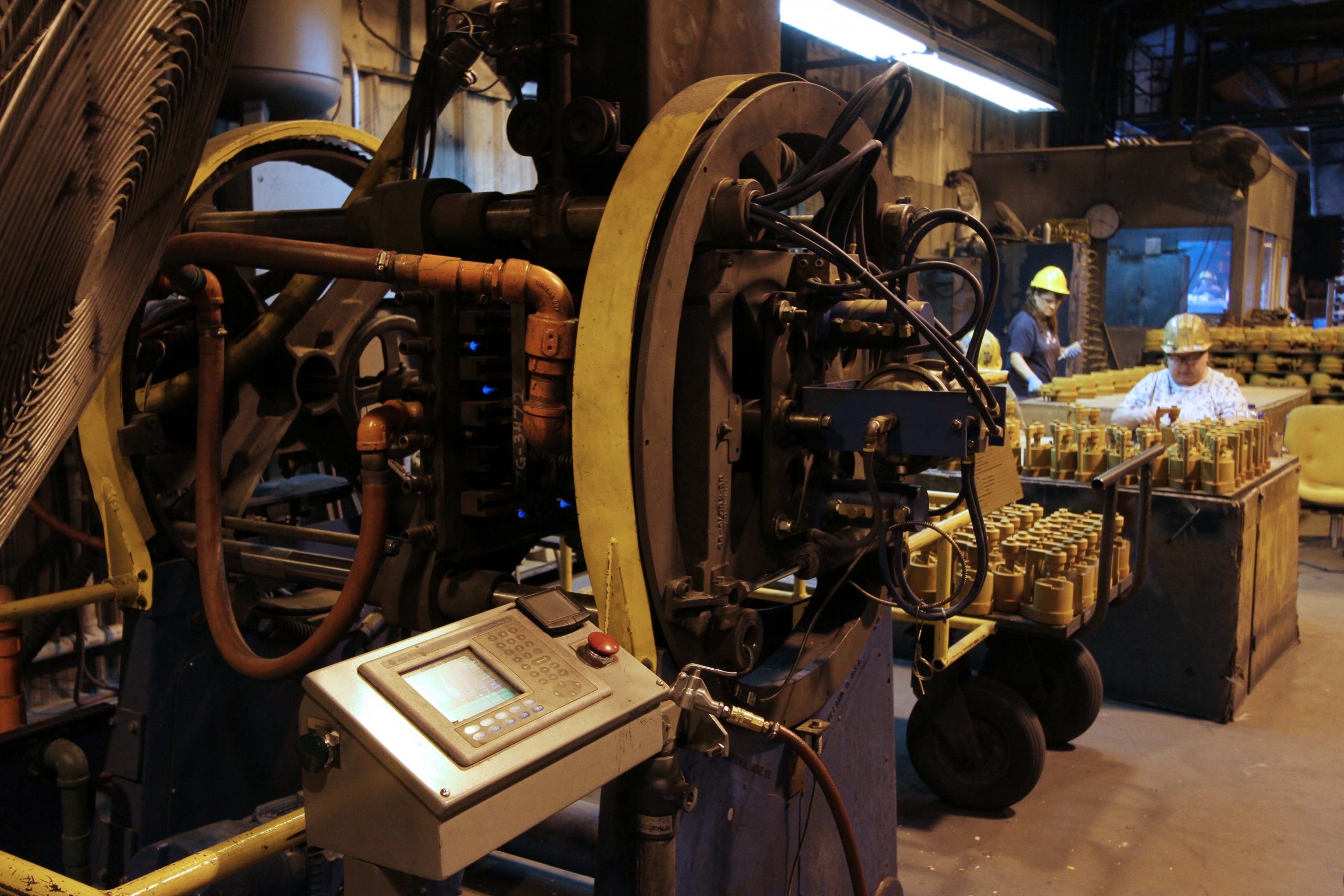

Core Room

Acme Foundry is outfitted with a state-of-the-art core room equipped to deliver all of your custom core-making needs. We specialize in manufacturing highly complex, cored and engineered gray iron castings.

Versatile, Customizable Core Making Services from the Experts in Gray Iron Castings

In the molding and casting process, a core is used to create internal cavities in complex molds. For complex cored products, a custom- manufactured core with precision tolerances is necessary to ensure the overall finished quality of the casting.

At Acme Foundry, we produce our custom engineered cores in-house to ensure the highest manufacturing consistency possible. We guarantee that your finished products are molded to your exact design, tolerances and specifications.

Outfitted with a Range of Cutting-Edge

Core Making Equipment & Technology

Core Room

- 12 – SF6 B&P Shell Core Machines

- 15 – U180 Shalco Shell Core Machines

- 1 – HS-22L Redford Horizontal Part Shell Core Machine

- 4 – Vertical Parting Redford Cold Box Machines

- 4 – Horizontal Parting Redford Cold Box Machines

- 1 – B&P Core Blower

- 1 – Dependable Sand Mixer

- 1 – Dependable Air Set Sand Mixer

- 2 – Beardsly Piper Top Blow Core Machines

- 1 – Horeback Core Dry Oven

- 1 – Crown Electric Pallet Jack

- 1 – Feco Automated Conveyor Core Oven