Acme Foundry specializes in manufacturing complex cored gray iron castings – both rough and machined. Maintaining accuracy and repeatability in casting these intricate products requires an extremely involved quality control process and inspection methodology.

The quality control technology used in foundries today is highly sophisticated, evolving alongside the industry’s increasing demand for precision-built products. From visual inspection and dimensional measurement tools to advanced metallurgical analysis equipment, Acme utilizes state-of-the-art techniques to achieve 100% complete customer satisfaction in terms of both quality and on-time delivery.

Our casting design experts can work with your custom 3D models or engineer a precision mold for the unique requirements of your application. In both cases, our finished castings are meticulously manufactured and confirmed to meet your exact specifications.

Coordinate Measurement Machines (CMMs)

Confirming accurate dimensionality is crucial – especially for precision cast products requiring exceptionally close tolerances and/or complex designs. When it comes to dimensional inspection and measurement of the products, advanced coordinate measurement machines (CMMs) provide us with highly accurate measurements of basic part dimensions as well as more intricate custom casting features.

CMMs and related tools are crucial to the quality control process, allowing our quality assurance experts to verify dimensions and part geometry meet the exact specifications of the design.

Automated Inspection Systems

We also implement various vision systems throughout our quality control process. Advanced visual inspection processes rely on cameras and other other image processing techniques to closely inspect castings for surface defects, dimensional accuracy, and overall quality.

We also implement various vision systems throughout our quality control process. Advanced visual inspection processes rely on cameras and other other image processing techniques to closely inspect castings for surface defects, dimensional accuracy, and overall quality.

With advanced computerized inspection methods, we can look much closer at the surface and into the material than is possible with conventional visual inspection.

Material Inspection and Metallurgical Analysis

The quality of the raw materials is crucial to the overall process. In many cases, we will implement material testing methods to confirm the material meets all physical/mechanical requirements, such as hardness and tensile strength. More advanced metallurgical inspection techniques can essentially look inside the material to confirm the quality at a molecular level. Most commonly, we can use spectroscopy techniques to analyze the chemical composition of raw metals to confirm the correct alloy mix before casting is underway.

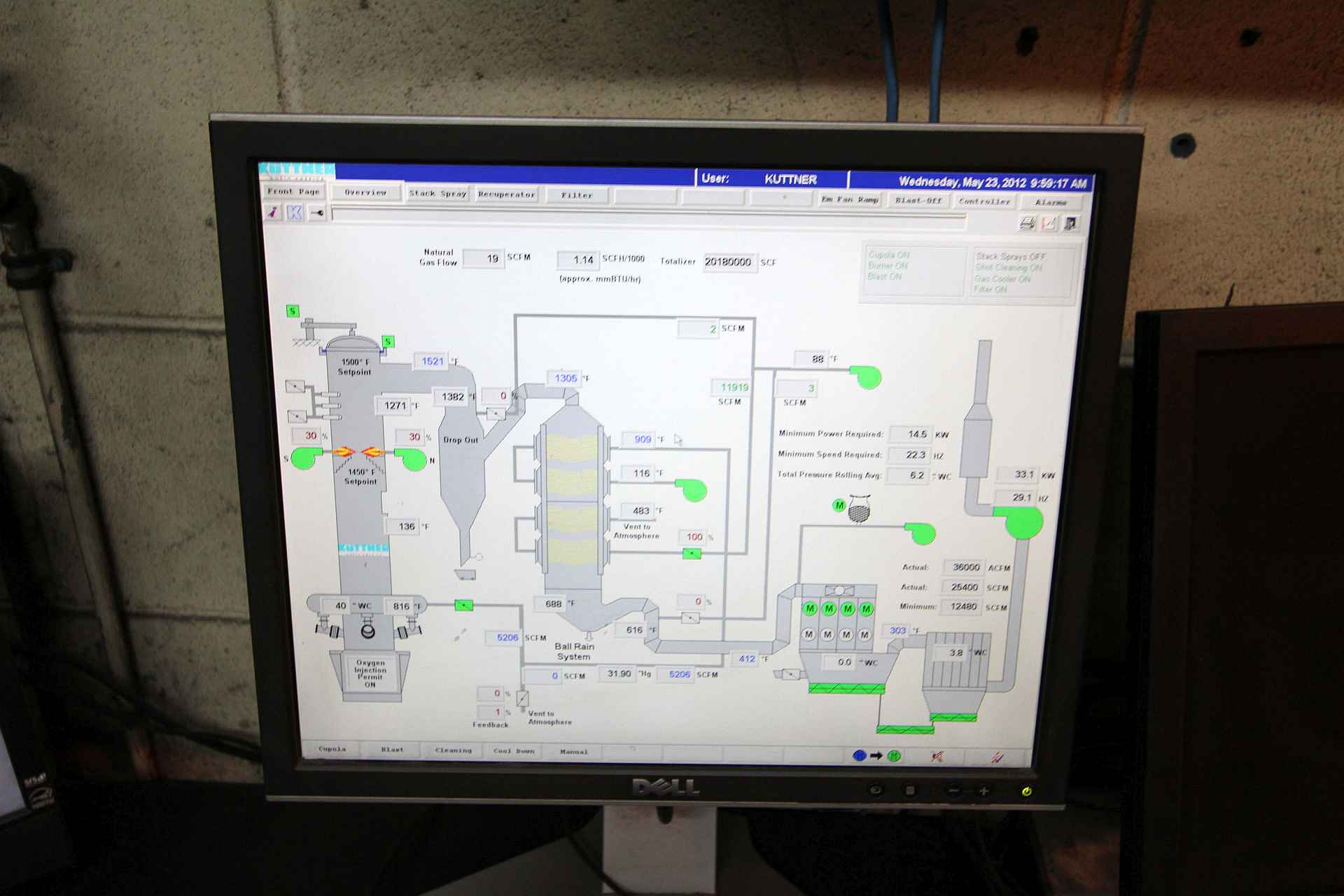

During the actual casting process, thermal analysis systems can monitor the solidification of the molten metal to ensure we achieve a proper microstructure for the required mechanical properties. The result is overall higher quality products that exhibit fewer material defects or manufacturing errors.

Quality American Foundry Services Since 1905

Backed by nearly 120 years of casting expertise, Acme is one of the nation’s most well-established foundries. Our commitment to quality control and superior craftsmanship allow us to meet even the most challenging of custom casting specifications.