Why Cast Iron Still Wins in 2026 – Manufacturing Material Showdown

As we head through 2026, we know that designers and engineers are under continued pressure to optimize their products, especially in terms of material usage. The major influences continue to be reducing total cost of ownership, managing supply chain risk, adopting cleaner processes, and yet delivering durable performance in demanding environments.

Amidst rising interest in high-strength steels, additive manufacturing, and exotic alloys, one iron-based material continues to hold its ground: gray cast iron.

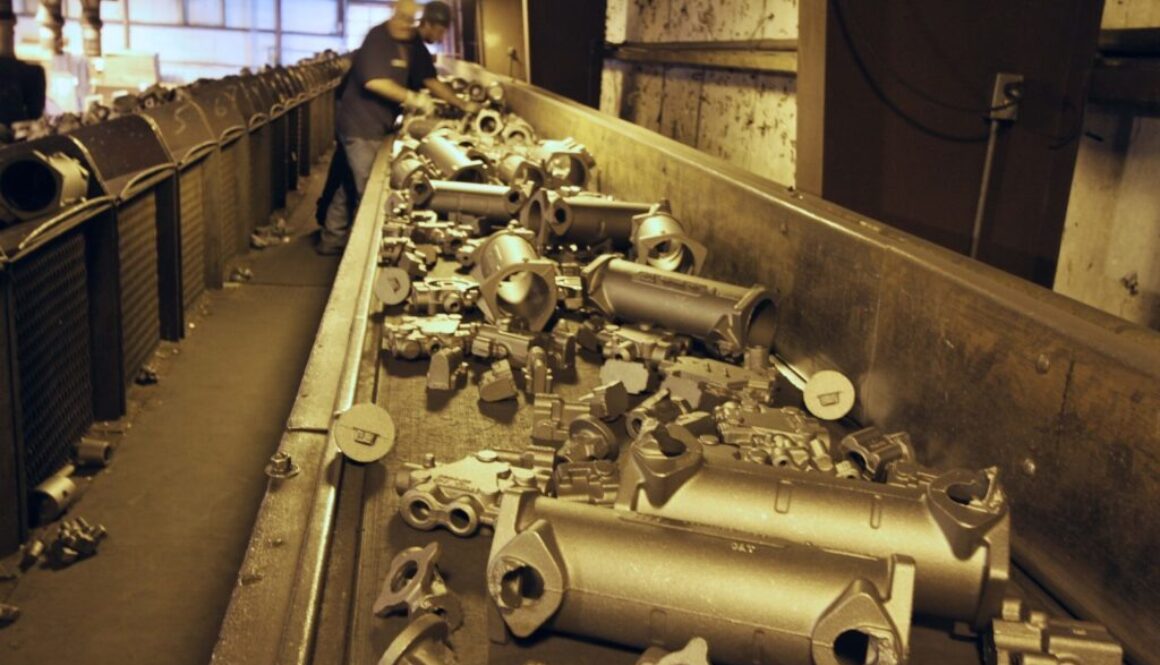

At Acme Foundry, we see increasing evidence that for many real-world applications, gray cast iron is still often the most pragmatic, cost-effective and reliable choice when compared to many competing non-iron materials such as carbon steels and low/alloy steels.

2025 Manufacturing Trends Informing 2026 Material Decisions

What were some of the major manufacturing headwinds from 2025 that are still influencing material selection as we head through 2026?

- Steady Growth in Iron and Steel Casting Market:According to industry forecasts, the combined iron and steel casting market is projected to grow from about USD 175 billion in 2025 onward. The iron side continues to command a large share of casting activity.

- Relatively Stable Cast Iron Lead Times vs. Steel Volatility:Throughout 2025, American cast iron foundries like Acme maintained relatively short lead times, while many steel mills (hot-rolled, cold-rolled) were reporting lead times of several weeks to months due to order backlog and raw material constraints. That gives cast iron an advantage for quicker turnaround in many industrial schedules.

- Marginal Softening in Steel Pricing: Some reports in 2025 show flat or gently declining base steel prices and sometimes lower surcharges, as mills try to clear inventory. While that helps reduce steel’s margin disadvantage, it doesn’t fully erase the broader advantages of cast iron in many use cases.

- Increased Attention to Circular Economy and Scrap Management:As steel industries push more toward electric arc furnaces and scrap-based cycles, scrap volume, quality, and cost are becoming more strategic. Some studies project that scrap trade dynamics will tighten, making feedstock management more challenging for steel suppliers. Cast iron, being less alloy-dependent and already deeply integrated into scrap / ferrous melt circuits, is relatively more flexible in feedstock sourcing.

Five Applications and Product Domains in 2026 Where Cast Iron Still Wins

Whether for material properties, performance, cost, or a combination therof, gray cast iron remains the go-to material for many modern end product applications.

1. Machine Tool Bases, Frames, and Beds

These machines demand strict control of vibration, thermal drift, rigidity, and accuracy. Cast iron’s damping, stability, and capacity for cast-in cavities (e.g. coolant channels, stiffening ribs) make it ideal. Using steel would typically require heavier sections, isolation mounts, or damping sub-structures.

2. Foundation Bases and Frames for Heavy Machinery

When mass, damping, and vibration suppression are valuable (rather than minimal weight), cast iron remains a cost-effective choice for foundations, chassis, and supports in industrial machines.

3. Gear Boxes, Housings, Bearing Supports

Lightweight structural steel housings are sometimes possible, but in many industrial gearboxes the ability to cast complex geometries (bearing seats, oil channels, ribs) and deliver integrated shapes gives cast iron a cost and performance edge.

4. Pump Volutes, Valve Bodies, Pipe Fittings

The complex internal flow paths and overall geometry are often more easily cast than machined or assembled from steel plates. Cast iron offers sufficient mechanical strength and excellent wear life in many scenarios.

5. Brake Rotors and Related Friction Elements in Heavy Duty Equipment

For heavy equipment, braking, and friction applications, cast iron still provides a good balance of thermal mass, machinability, wear performance and cost. For ultra-high performance or lighter weight designs, advanced steels or composites may be justified — but for many standard applications, cast iron remains the default.

Cast Iron Material Expertise for Your Project

In 2026, the material landscape for manufacturing is increasingly complex: additive processes, exotic alloys, global supply constraints, and sustainability pressures all shape decisions. Yet in that evolving arena, gray cast iron remains a prime choice for many industrial components and consumer products alike—not out of tradition, but out of competitive practicality.

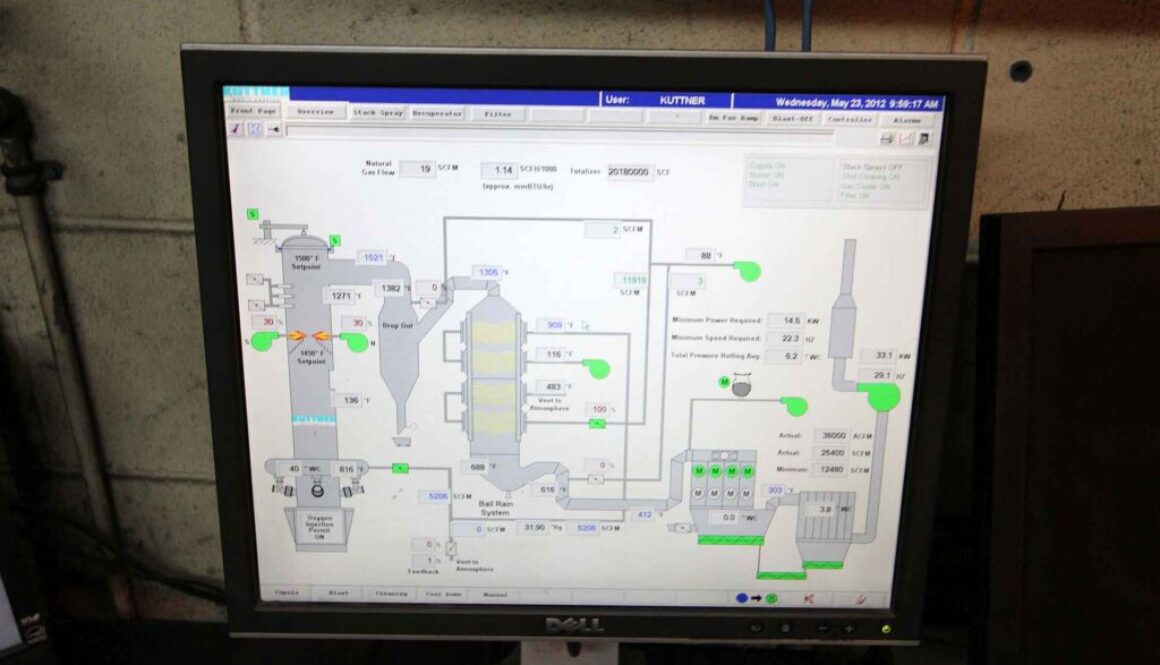

Its combination of cost-competitiveness, vibration damping, manufacturability, supply resilience, and predictable behavior often puts it ahead of many steel options for medium- to high-volume industrial parts. At Acme Foundry, we continue to invest in core capability, process control, and simulation-driven casting design so that engineers who choose cast iron gain a modern, efficient, and high-value component solution.